How to Choose the Right Print Inspection Systems for Your Business?

In today's competitive printing industry, selecting the right Print Inspection Systems is crucial. Experts agree on the importance of quality control. John Smith, a leading authority in print technology, emphasizes, "A reliable inspection system is key to maintaining standards." This statement reflects the industry's focus on precision and quality assurance.

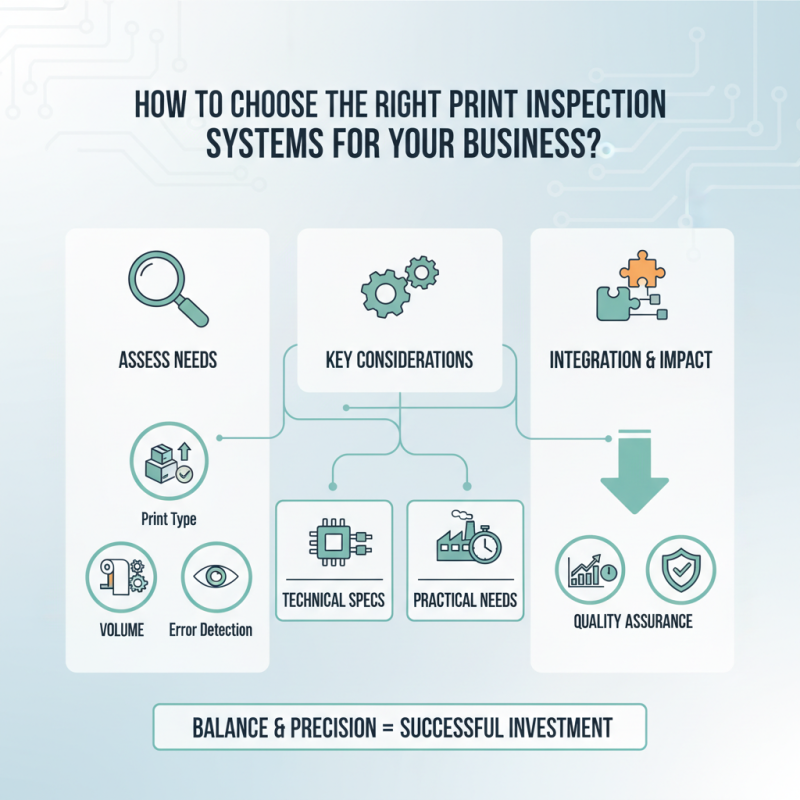

When considering Print Inspection Systems, businesses must assess their specific needs. Factors such as print type, volume, and error detection capabilities play a significant role. Each company may have a unique set of challenges. For example, a high-speed label printer may require different inspection features compared to a specialized packaging line.

Moreover, the integration of these systems can be complex. Sometimes, organizations might overlook compatibility issues with existing machinery. Such oversights can lead to inefficiencies. As businesses navigate their options, it’s essential to explore all angles and recognize that the right choice can significantly impact productivity and quality. Balancing technical specifications with practical needs is vital for a successful investment in Print Inspection Systems.

How Print Inspection Systems Enhance Quality Control in Manufacturing

Print inspection systems play a crucial role in enhancing quality control in manufacturing. These systems help detect defects early in the production process. According to a recent report, 30% of manufacturing errors can be attributed to undetected print flaws. Such flaws can lead to increased waste and customer dissatisfaction. By implementing print inspection, businesses can reduce these errors significantly.

Data shows that companies using print inspection systems report a 50% decrease in rework costs. It’s a tangible benefit. Automated systems can inspect products at high speeds, catching issues that manual checks might miss. Yet, the integration of these systems isn't always straightforward. Some businesses struggle with the transition due to outdated processes or lack of training.

In a competitive landscape, failing to adopt effective inspection methods can be detrimental. For instance, a study indicated that 20% of production delays are caused by quality control failures. Companies must reflect on their current practices. Embracing new technology may require adjustments in staff training and workflow.

Key Factors to Consider When Selecting Print Inspection Technology

Choosing the right print inspection systems is crucial for maintaining quality in production lines. One key factor is understanding your specific needs. For example, a report from Smithers found that 70% of packaging failures relate to print issues. It's essential to identify what aspects to monitor. Color accuracy, barcode readability, and defect detection are critical elements.

Another factor is the integration capability of the system. Many operations report difficulties in implementing new technology. A survey indicated that around 40% of manufacturers faced challenges in integrating print inspection with existing machinery. This issue can disrupt workflow and lead to significant downtime. Selecting a system that easily fits into your current setup can lower these risks.

Cost is also a major consideration. High-end systems may seem appealing. However, they require substantial initial investments. A balance between cost and functionality is necessary. It's vital to evaluate potential returns on investment. Systems that can enhance throughput and reduce waste may offer better long-term value. An informed choice will depend on a mix of these factors, emphasizing the importance of careful evaluation.

Print Inspection Technology Comparison

This chart illustrates the effectiveness of different print inspection technologies. Automated inspection offers the highest effectiveness at 90%, followed by inline inspection at 85%, manual inspection at 70%, and offline inspection at 60%. These metrics can help businesses select the most suitable print inspection system based on their quality assurance needs.

Comparative Analysis of Different Print Inspection Methods

When selecting print inspection systems, understanding different methods is vital. There are several approaches to consider. Inline inspection systems detect defects during production. They provide immediate feedback. However, they can be intrusive and may slow down the process. Research shows that around 35% of manufacturers face challenges with inline setups.

Another approach is offline inspection, where printed materials are checked separately after production. While this method ensures thorough evaluations, it can also lead to delays. A study revealed that 50% of companies experienced longer turnaround times with offline systems.

Furthermore, automated visual inspection technologies are gaining traction. They can identify defects at a higher accuracy rate, yet they require constant updates and maintenance.

Consider the data showing that up to 30% of print defects remain undetected with traditional methods. Regularly reassessing your inspection strategy is crucial. Businesses must reflect on the limitations of their current practices and explore innovative solutions to improve quality control. The choice of a print inspection method will shape your operations significantly.

Integration of Print Inspection Systems with Existing Production Lines

Choosing the right print inspection system involves understanding integration with existing production lines. An effective system must align with your current workflows. Research shows that around 80% of manufacturers struggle with this integration. They often experience workflow disruptions or technical glitches.

When selecting a system, consider compatibility. An ideal print inspection solution will seamlessly connect with your printers and other machinery. Data from industry reports highlight that companies often report a 30% reduction in errors after successful integration. This metric underscores the importance of choosing wisely.

Tip: Conduct pilot tests before full implementation. This helps identify potential issues early. Understanding specific requirements is essential for a smooth transition. Train staff on new technologies to minimize resistance.

Many companies overlook the need for ongoing support. Systems may require updates or adjustments over time. Industry standards suggest regular evaluations of the systems to ensure they meet evolving needs. Be prepared to iterate on your processes to maintain efficiency.

The Future Trends in Print Inspection Technology and Their Implications

The landscape of print inspection technology is rapidly evolving. Recent reports highlight that the market for print inspection systems is expected to grow at a CAGR of over 6% through 2030. As businesses strive for higher quality, integrating advanced inspection technologies becomes crucial. Machine vision systems now utilize artificial intelligence to detect imperfections. This has changed how print quality is managed.

One prominent trend is the adoption of smart sensors and real-time analytics. These technologies allow for immediate adjustments during the printing process. A survey shows that about 70% of manufacturers see increased efficiency from implementing such systems. However, many companies struggle to fully utilize these advancements. A common limitation is the integration of new technology with existing workflows. Training staff to adapt to these systems is another challenge.

Additionally, sustainability is gaining importance in print inspection. Current studies indicate that 40% of companies plan to invest in eco-friendly inspection solutions within the next five years. While this is promising, there are questions about cost-effectiveness. Not all companies can afford the latest technologies. Businesses must reflect on their specific needs and budgets when making investment decisions. This complexity can lead to oversight and misguided choices. The future also hints at automation, yet not every operation is ready for such a leap.

Article Source:

Quality Commercial LED Lighting specializing in LED Tubes, LED Bulbs, LED Troffers, LED Door Kits, LED Retrofit Kits, LED Panels, LED Spot Lights, LED Wall Packs, LED Lamps, LED Drivers, LED Accessories, LED Lights, LED Sales, and LED Manufacturing. Headquartered in Atlanta, Georgia, USA.