Top 10 Benefits of Aluminum Wire Coating for Durability?

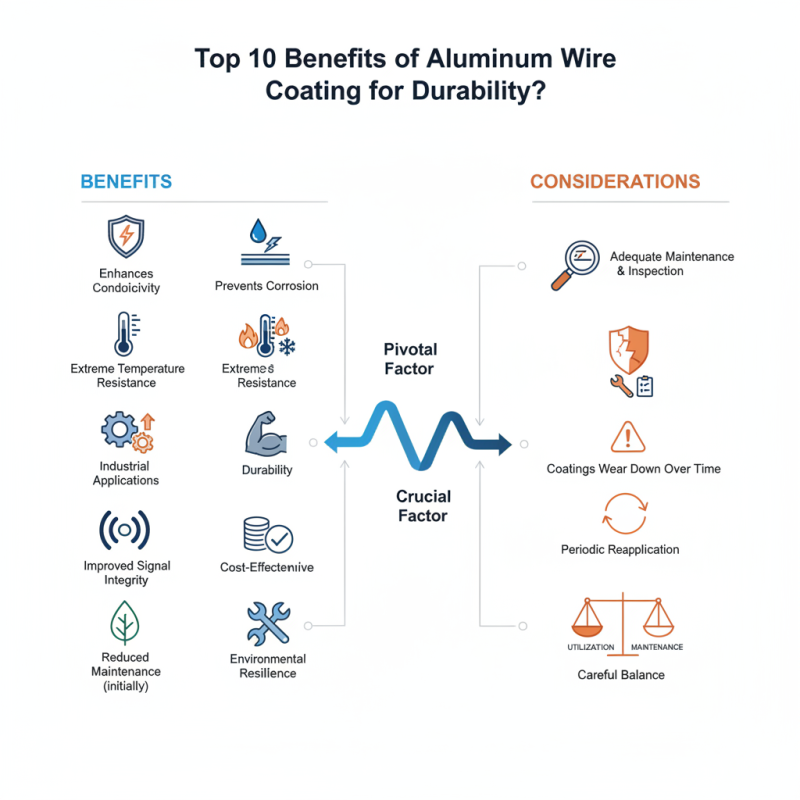

In the world of industrial applications, "Aluminum Wire Coating" has emerged as a pivotal factor for enhancing durability. According to renowned expert Dr. Emily Carter, "The right coating can significantly extend the lifespan of aluminum wires." This emphasizes the crucial role of protective coatings in various sectors.

Aluminum Wire Coating provides numerous advantages. It prevents corrosion, enhances conductivity, and offers resistance to extreme temperatures. Many industries rely on this technology for its resilience. Yet, users often overlook the need for adequate maintenance and inspection. Regular checks can reveal hidden issues that coatings can't entirely defend against.

Moreover, while the benefits are evident, it's essential to recognize the limitations. Coatings may wear down over time, requiring periodic reapplication. Understanding these nuances leads to better decision-making. Therefore, a careful balance between utilization and maintenance of Aluminum Wire Coating is key to maximizing its potential.

Benefits of Aluminum Wire Coating for Enhanced Durability

Aluminum wire coating offers a range of benefits, particularly for enhancing durability. One of the key advantages is its resistance to corrosion. This property is crucial in environments where moisture and chemicals are prevalent. Coated aluminum wires last longer and maintain their functionality over time. Users often notice fewer maintenance issues, which result in reduced costs.

Another significant benefit is improved electrical insulation. The coating helps prevent short circuits and other electrical failures. This is particularly important in industrial applications where safety is paramount. However, it's worth contemplating the potential downsides, such as the initial investment in coated wires. In some cases, the coating might not adhere perfectly, leading to performance issues.

Overall, the enhanced durability of aluminum wire coating translates into better long-term performance. Despite some imperfections, the advantages often outweigh the drawbacks. Many industries can benefit from this technology, but careful consideration is necessary.

Understanding the Process of Aluminum Wire Coating

Aluminum wire coating enhances longevity and strength. This process involves applying a protective layer to aluminum wires. The coating increases resistance to corrosion and wear. It also improves electrical conductivity. Understanding this process can help in many applications.

Tips: Choose the right coating material based on your project's needs. Consider factors like environment and usage. Even minor oversights in selection can lead to failures.

The coating process can vary in complexity. It usually involves surface preparation, applying the coating, and curing. Surface prep is critical for adhesion. Any contaminants can result in peeling or flaking.

Tips: Always clean the surface thoroughly before coating. Using the wrong cleaner can cause issues later. If the wire is damaged before coating, the durability will be compromised.

Top 10 Benefits of Aluminum Wire Coating for Durability

| Benefit | Description |

|---|---|

| Enhanced Corrosion Resistance | Aluminum coatings protect against oxidation and extend lifespan. |

| Improved Conductivity | Coated aluminum maintains high electrical conductivity for efficiency. |

| Weight Reduction | Aluminum is lighter than other metals, reducing overall system weight. |

| Cost-Effectiveness | Lower material cost compared to copper, decreasing project expenses. |

| Thermal Stability | Coatings enhance resistance to high temperatures and thermal cycling. |

| Absence of Toxicity | Non-toxic coatings are safer for workers and the environment. |

| Aesthetic Appeal | Coatings can be colored, improving visual design and branding. |

| Flexibility in Applications | Suitable for various applications including electrical and structural uses. |

| Easy Maintenance | Coated surfaces require less maintenance, saving time and costs. |

| Longer Lifespan | Overall durability leads to reduced replacement frequency and costs. |

Comparative Analysis: Aluminum Coating vs. Other Coatings

When comparing aluminum coatings to other options, several factors highlight their advantages. Aluminum coatings are known for their superior durability. They resist corrosion effectively, especially in harsh environments. This makes them a smart choice for outdoor applications where exposure to moisture and air is a concern. Other coatings may not perform as well in preventing rust or degradation.

One significant area to consider is weight. Aluminum is lighter than many alternatives. This can lead to easier installation and less strain on structures. Moreover, aluminum coatings often provide better thermal conductivity. This means they can reflect heat effectively. Some coatings just can’t match this efficiency.

**Tip:** Always evaluate the specific needs of your project. What works for one environment may fail in another.

Another point to ponder is cost. While aluminum coatings might seem more expensive upfront, their longevity can lead to savings over time. Lower maintenance costs and fewer replacements can make a significant difference. In contrast, other coatings may require frequent upkeep.

**Tip:** Don’t overlook long-term budgeting when choosing materials. A cheaper option now can lead to costly repairs later. Always consider durability versus initial expense.

Assessing the pros and cons of each coating type is crucial. Not every project requires the same solution. Take time to research and reflect on the best fit for your needs.

Environmental Resistance: How Coating Extends Wire Lifespan

Aluminum wire coating offers multiple advantages, particularly in environmental resistance. Coatings protect against moisture, corrosion, and temperature extremes. These elements can drastically reduce wire lifespan if left uncoated. With a strong coating, wires can withstand harsh conditions. This is crucial for outdoor applications, where exposure is inevitable.

One key tip for extending wire longevity is regular maintenance. Inspect for any signs of damage. Look for cracked or peeling areas. Address these problems early to avoid bigger issues. Another tip involves selecting the right coating for your environment. Consider factors like humidity, salt exposure, or chemical contacts. A tailored approach can significantly enhance durability.

While coatings provide protection, they're not infallible. Over time, even the best coatings can wear down. Regular checks help identify when replacements are necessary. Don’t forget that improper installation can lead to vulnerabilities. Ensure your coating is applied correctly for optimal results.

Cost-Effectiveness of Aluminum Wire Coating in Long-Term Use

Aluminum wire coating offers substantial cost-effectiveness in the long run. This technique creates a protective layer that enhances the wire's durability. Consequently, it reduces the need for frequent replacements and repairs. Long-lasting performance translates into lower material and labor costs over time. In many cases, the initial investment is quickly recovered.

Investing in aluminum wire coating can lead to improved efficiency. Maintenance becomes less of a burden. When wires resist corrosion and wear, downtime decreases. However, it's essential to remember that not all applications can utilize aluminum wire effectively. Specific environments may present challenges. Proper assessment is critical before making a decision.

The adaptability of aluminum wire coating to various situations is a benefit. Yet, it sometimes lacks compatibility with older infrastructure. Companies could face unexpected costs related to adaptations. Despite these challenges, most users find that the advantages outweigh the drawbacks. The focus on longevity and affordability makes aluminum wire a smart choice for many industries.

Article Source:

Quality Commercial LED Lighting specializing in LED Tubes, LED Bulbs, LED Troffers, LED Door Kits, LED Retrofit Kits, LED Panels, LED Spot Lights, LED Wall Packs, LED Lamps, LED Drivers, LED Accessories, LED Lights, LED Sales, and LED Manufacturing. Headquartered in Atlanta, Georgia, USA.